ARCHAEOLOGY AT THE MARMORA IRONWORKS

RESULTS OF THE 1984 FIELD SEASON

By Gray Graffam

(Erratum: " It seems that in the process of editing my manuscript, the references to Arthur Dunn' s work were removed. I had cited him in several instances: in the history section for his article in JHMS, and at spots in the text for personal communication. G. Graffam")

INTRODUCTION

Although the Marmora Ironworks failed repeatedly as an economic venture in the 1820-1860 period, it was an important early attempt at industrial development. An outline of the documentary sources and the results of preliminary archaeological investigations show that the site may contribute to a fuller understanding of the economic, technological and social history of this early period of settlement in Upper Canada.

During the summer of 1984 Trent University conducted a field school at the Marmora Ironworks site in eastern Ontario. This paper presents a brief history of the site, which serves to delineate some of the issues addressed archaeologically, and the results of the 1984 season. The research potential of the site is considered from the viewpoint of technology, lifeways, social process and current themes in comparative research.

SITE LOCATION AND HISTORY

The Marmora Ironworks site is located on the eastern bank and bluff of the Crowe River, just north of Highway 7 in Marmora, Ontario (Fig. 1). The factors that influenced site location were identified through an examination of historical sources, geological information on mineral resources, and hydrological information on water power. Historical sources documented that the Canadian government promoted the establishment of an ironworks within the "interior" of Upper Canada. This was done as a mean of guaranteeing a local supply of iron to the Kingston naval base and dockyards and thereby enhance their security (Craig 1963:85-87). Having experienced difficulties in obtaining sufficient quantities of iron at a reasonable price during the War of 1812, the Canadian government sought to develop a stable, local supply. Government land grants and naval contracts for iron ballast were made available to encourage industrial development north of Lake Ontario (Pentland 1981:219)

Negotiations to build an ironworks in the interior area were begun in 1816 by William Henderson (Pentland 1981:246) but the terms were apparently not satisfactory to the merchant and steps to build an ironworks were not undertaken. In 1819 plans were formed by Charles Hayes to construct an ironworks along the Crowe River. Although there were earlier ironworks in Upper Canada, the furnaces constructed at Lansdowne about 1800 and at Potter's Creek (Normandale) in 1813 (Royal Commission 1890:319), the Marmora site was the first in a "protected" location some distance from the New York border. In addition, it was an attempt to establish an industry using magnetic and hematitic ores and hence produce a high quality iron.

The location at Marmora presented several advantages from a technological perspective as well. The costs of mining and transporting ore, and the costs of carting fuel were undoubtedly major considerations for the smelting industry. Magnetite and hematite deposits were regularly found at the surface within the Precambrian Shield, whereas further south they were covered by Ordovician limestone. However, hardwoods were more extensive south of the Shield and these made a more efficient and preferred fuel. Thus it was most efficient to locate where both hardwoods and easily mined resources were available—along the edge of the Precambrian Shield.

A further consideration was the economics of transport to market, coupled with the availability of sufficient waterpower to drive the ironworks machinery. Transport along water routes was less costly than overland routes, except where portages were frequent and lengthy. Therefore transportation via the Trent River from the town of Stirling to the Bay of Quinte on Lake Ontario appeared attractive since it was anticipated that the naval yard at Kingston would be a major market for iron. This left only a 14 mile section between the ore site and the navigable Trent waterway, and therefore it allowed the industry to develop along the Crowe River at present-day Marmora. The 12-foot waterdrop at the Marmora site was one of the best available for powering the ironworks and thus the site appeared quite attractive.

The history of the industry can be divided to five periods:

- Charles Hayes and the Period of Establishment, 1819-1825;

- Peter McGill and Subsequent Attempts at Development, 1825-1847;

- Joseph Van Norman and Renewed Investment 1847-1854;

- The Marmora Iron Company 1854-1866;

- The Cobourg, Peterborough, and Marmora Railway and Mining Company, 1866-1882.

These periods coincide with title transactions of the property, and they form the first phase of Marmora's history. Only a modest amount of archival material exists for the industry (Crevier 1985).For the Hayes Period there are the letters of communication between Hayes and various government officials, records of land petitions, and the advertisements and editorials in The Kingston Chronicle. For the McGill, Van Norman, and Marmora Iron Company periods, archival sources include land deeds, census returns, Statutes of Upper Canada, Report of the Removal of the Penitentiary from Kingston to Marmora by Manahan and Ridley within the Buchanan Papers, editorials and advertisements in The Kingston Chronicle and The Kingston Chronicle and Gazette and the McGill Papers at McGill University. For the period of the Cobourg, Peterborough, and Marmora Railway and Mining Company archival materials include editorials in The Intelligencer and The Hastings Chronicle, various pieces of correspondence, and financial accounts preserved at the Peterborough Centennial Museum. Of particular value to all of the periods is the Report of the Royal Commission on the Mineral Resources of Ontario and Measurers for Their Development which was issued in 1890 by order of the Legislative Assembly.

Only the highlights of the history of the industry need be touched on here. During the Hayes Period, the industry was founded and a number of buildings were constructed. As shown by an 1826 map (Fig. 2), these included 5 dwelling houses, 8 double occupancy worker cottages (16 families), 1 school house, 1 forge, 2 furnaces, 1 casting house, 1 gristmill, 1 sawmill, 1 tannery, and a variety of associated structures. Given the prominence of the Marmora Ironworks at this time, it was most likely similar to other single enterprise communities in Canada; workers and their families were dependent upon the industry for providing their support, and material goods were likely purchased through the company. But the industry was not entirely successful during the Hayes Period. This may have been partly due to the problems of "vile and disorderly conduct" on the part of his workmen (Palmer 1983:36), but essentially it was a consequence of overinvestment with too little return. During the 1819 to 1825 period Hayes poured 230,000 into the ironworks (Hayes 1828) but revenues from the sale of iron ballast totalled only 213,000 (Manahan and Ridley 1839:4). Revenues from the sale of cast hollow ware are unknown, but they were evidently insufficient to offset the incurred debt. Hayes was unable to raise working capital (Hayes 1828), and hence he was forced to turn over the works to his principle creditors, Peter McGill, Anthony Manahan, and Robert Hayes (HCRO Deeds).

Map redrawn for clarity

During the McGill Period attempts were made to continue the industry. Iron ballast and cast iron ware were produced during the years immediately following Hayes's departure (Manahan and Ridley 1839:7-10). However, this attempt to maintain the industry also failed. The annual interest (1200) on the incurred debt was too high (Hetherington 1830:3). Apparently sufficient revenues were not obtained by the enterprise, either due to insufficient production of cast wares or the lower prices of competitors. Various attempts were made to adjust the situation, for instance to obtain banking privileges, to obtain railway contracts, and to have the government relocate the Kingston Penitentiary to Marmora (Crevier 1985).These attempts to finance the ironworks also failed and the industry was sold at a loss.

Following the purchase of the site by Van Norman, further investment into the industry is recorded. A large sum" was spent to set up the furnaces, and to install ovens and blowing apparatus at the site (Royal Commission 1890:321).The improvements were intended to make the operation more profitable by enhancing the output of the furnace and reducing the quantity of fuel needed. Unfortunately these improvements were not sufficient to offset the changes that were taking place in the marketplace at a time when the Marmora Ironworks faced severe competition after the opening of the Saint Lawrence canal (Royal Commission 1890:321-322). Lacking a sufficient return, Van Norman was forced to sell the enterprise at a substantial loss.

When the Marmora Iron Company took over the industry, they also placed a substantial investment into the ironworks (Royal Commission 1890:322). It was anticipated at that time that the industry could become successful if sufficient capital could be raised, and if transportation to market was done by rail (SUC 1857). Unfortunately, sufficient technical expertise was not at hand, and the first attempts at producing iron either ended in failure or in substantially reduced production. Transportation by rail was never realized and the industry again collapsed, this time costing the investors £75,000 (Royal Commission 1890:322).

The Marmora Iron Company, however, continued to exist, although production at the site ceased in the 1850s. In December, 1866, the company amalgamated with the Cobourg and Peterborough Railway Company and thus received a substantial economic boost (SUC 1865).However, the advent of more efficient technologies elsewhere at this time made charcoal-iron less competitive throughout Canada (Inwood 1983:1-6), and no efforts were made to revive the Marmora Ironworks. Rather, the ore from the nearby mine at Blairton was extracted for sale to companies in the United States (Crevier 1985). The most productive years of this arrangement were from 1868 to 1873, and by 1882 a total of over 250,000tons of ore had been exported (CVCA 1974:50-52).

Following the closure of the Blairton Iron Mine, Thomas Pearce obtained the property of the Cobourg, Peterborough, and Marmora Railway and Mining Company (HCRO Deeds). A sawmill enterprise was constructed at the site of the Marmora Ironworks, and the abandoned buildings of the earlier industry were probably torn down at that time.

Before leaving the section on history, it would be valuable to point out some of the changes that likely occurred in the community during its first phase of development. In order to do this, we may compare Marmora Township and Rawdon Township, an agricultural township immediately to the south of Marmora. As shown in Table 1, the 1861 population of Marmora Township was 1,499 and that of Rawdon Township was 3,591. The number of families for each community was respectively, 209 and 686. What was most striking was the size of the male work force (the number of males over 16)in each area. In Marmora, the total male work force was 558, or 37% of the population. In Rawdon the total male work force was 878 or only 24% of the population. We have assumed here that only a negligible number of adult males were retired or economically inactive. This was probably reasonable as there was no enforced retirement and pensions, and farmers tended to remain active until advanced years. The single largest difference between the two labor forces was in terms of the number of laborers.

Laborers in Marmora Township accounted for 44% of the work force, whereas in Rawdon Township they accounted for only 34%. The term laborers included both industrial and agricultural workers, since census returns did not specify workplace. However, agriculture certainly did not account for the high number of laborers in Marmora. The proportion of agricultural to industrial laborers in Marmora Township may be estimated by assuming that each farmer in Marmora hired the same number of laborers as in Rawdon. The ratio in Rawdon was 1:0.59 (farmers:laborers), which means that Marmora would have had 110 agricultural laborers—59% of the number of farmers (187). An alternate method would be to use Rawdon 's ratio of cultivated acres to laborer (79:laborer), which predicts 80 agricultural laborers in Marmora. However, the actual number of laborers in the northern township was more than double the largest of the estimates—245. Thus, at least 135 laborers, and perhaps as many as 165, were likely employed in non-agricultural activities. This was a substantial portion of Marmora's work force—up to 67% of the laborer sector—and to a great extent attributable to the iron industry of Marmora Village.

The high number of male laborers in the population almost certainly accounted for the imbalance in the adult male to adult female ratio in Marmora Township. The number of adult males when Marmora was first settled was three times that of the number of adult females in the town. This imbalance was likely due to the labor force that was needed to build and run the Marmora Ironworks, because laborers in general were less likely than others to be married, and this was probably particularly so for laborers who newly moved to an industrial village. The imbalance indicates that the initial settlement of Marmora Village was not family based, and that individual men initially formed a strong component of the local society and economy. The imbalance was greatest during initial settlement, but remained substantial throughout the first half of the nineteenth century.

In time the number of adult men and women gradually became more equal and eventually it mirrored that of Rawdon Township. This was in part the result of the industrial laborers establishing themselves and marrying women from outside communities. However, after 1856, it may also have been due to the collapse of the ironworks industry and the departure of its work force. The laborers at that time were forced either to shift to a different vocation or to relocate. The development of the mining industry at nearby Blairton (Belmont Township) in the late 1860sand 1870sprobably attracted many as did the opening of other mines in adjacent townships.

Following the close of the ironworks Marmora Village changed. Although further historical research is needed to complete the profile of the community during this time, it is likely that the second phase of Marmora's history saw the establishment of more craftsmen and professionals in the village. The neighborhood that had been worker housing developed into a thriving centre and hence changed the social structure of the area.

RESEARCH ORIENTATION AND METHODS

The objective of the 1984 field season was to assess the various features and deposits of the Marmora Ironworks site, and to outline avenues for future research. In addition, it was designed to provide background research on the factors that influenced site location and patterns of overall socioeconomic development.

There were several reasons why the Marmora Ironworks site was selected for historical archaeological research. The site offered the potential to address aspects of early iron technology in Upper Canada from 1820 to about 1860 (Michael 1983:134) when techniques of iron smelting were rapidly changing. In addition, since the ironworks repeatedly failed, worker housing areas offered the potential to address shifts in Canadian settlement. Thus, both technological and social processes were identified as potential themes for examination.

The methods for assessing the site included an historical study of impacts to the site, and an archaeological study of features and sub-surface deposits. The historical assessment concentrated on historical maps and oral history information that indicated substantial landscape modifications. An overlay of maps was made to study the affects of a late nineteenth-century and twentieth-century building program at the site. This included the realignment of the dam structures and the placement of sawmills and associated structures at the site. Oral history information was gathered to provide further details on how the site has been changed over time. The archaeological assessment first divided the research area into four subareas: mill area, forge area, furnace area, and worker housing area. Each sub-area corresponded to a major unit of the ironworks site. An electromagnetic survey was conducted over the mill, forge, and furnace areas, and historical maps were used in an attempt to target historical structures of the ironworks. Test trenches were used to assess the nature of the features and strata in these areas. Excavation was not undertaken where the historical assessment indicated little or no potential for intact ruins of these structures. The overburden of sand from the previous excavation in the furnace area was removed to assess the nature of that area. Surface collection of artifacts within backyard gardens and test units adjacent to front yards were used to assess the worker housing along present-day Main Street. Soils were screened through 1/4inch mesh, and most excavation done with trowels (Graffam 1985).

RESULTS

The mill area was assessed through historical documentation which indicated that little to no potential existed for examining intact features and deposits of the early structures within that area. Oral history and historical research indicated that the main dam area had been extensively disturbed in the past. The building program of the later Pearce Company had likely obliterated the earlier structures in this area and recent alterations in the course of the main dam and blasting to widen the sluiceways had likely done further damage.

The forge area was assessed though limited test excavations in areas thought to be potentially significant according to historical maps and the electromagnetic survey. Although historical research and oral history indicated that the northeast part of the structure had undoubtedly been impacted, some potential was anticipated for the remaining portions of the structure. Test results, however, were negative and it became apparent that extensive historical fill had been placed over all of this area.

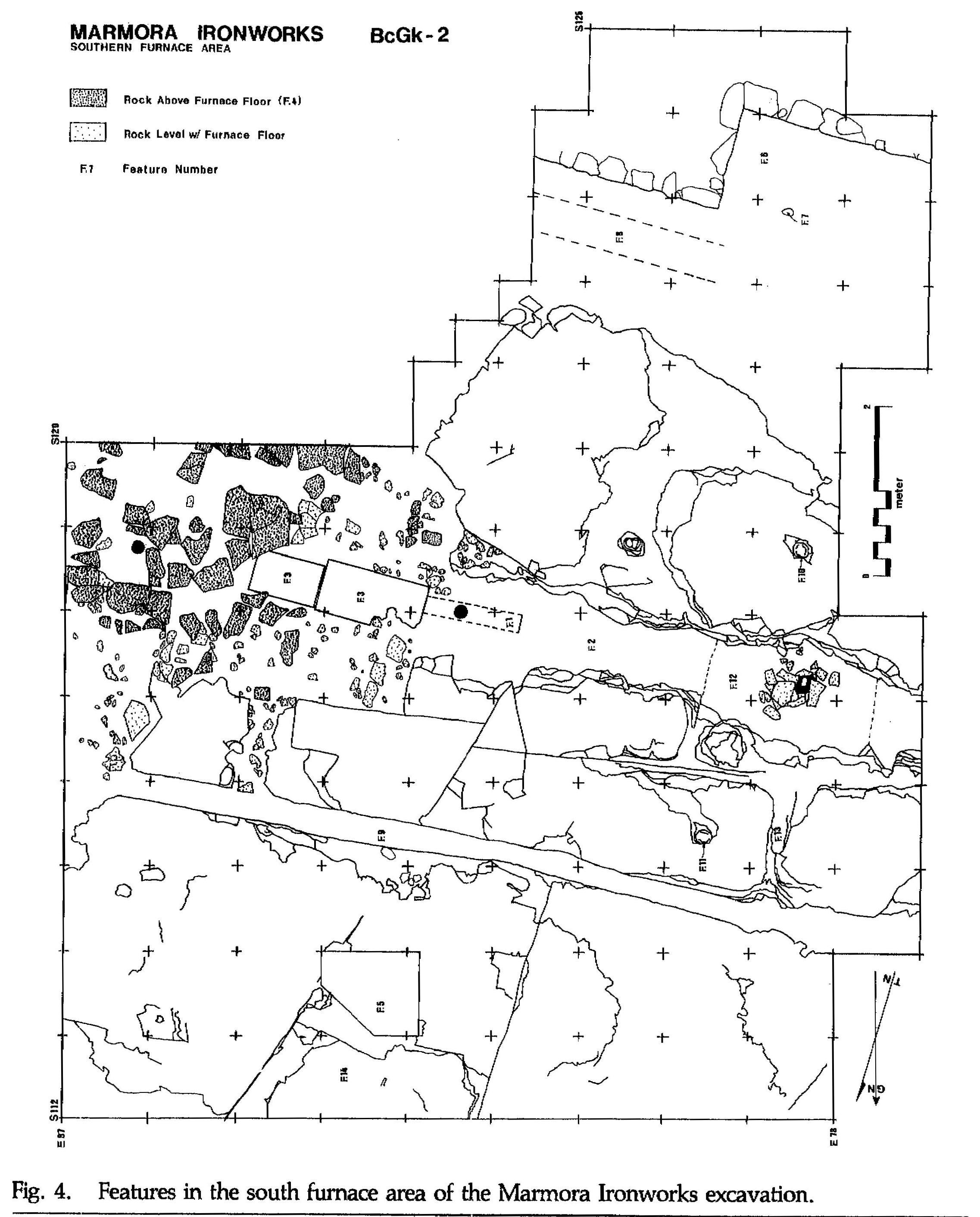

The intact features of the furnace area were recorded after removal of the overburden of the previous excavation and through limited test excavation in areas that were indicated by historical maps and the electromagnetic survey (Fig. 3). A total of 15 features were found in the area that had been previously excavated (Fig. 4), including those associated with water power (F6), drainage (F2, 8), blast operation (Fl, 10, 11, 12), and structural support (F3, 4). In particular F5 is an iron "bear" (accumulated mass of iron at the base of the furnace as the blast ceases) which serves to document the 20" x 48" (51 cm x 122 cm) size of the southern furnace hearth for what was probably the 1854-1866 period. Also F10, 11, 12, 15 demonstrate that a blowing engine had been used to power the blast. F10 and 11 are cup-shaped depressions that likely held the legs of such an apparatus, F12 connected to the blowing engine and delivered the air blast to pipe receivers (F1 is an example), and F15 is a group of oil stains that had soaked into the porous bedrock. This evidence probably relates to the improvements made by Van Norman, or the later Marmora Iron Company, when a "blowing apparatus" was set up at the site (Royal Commission 1890:321).

A total of 9 features were found within 2 test trenches that were placed over the northern part of the furnace area (Fig. 5). These included structural features (F20, 21, 27), historical fills (F22, 24, 25), and demolition debris (F23, 26). These features indicate that the entirety of the furnace area has intact features and document aspects of site construction. In particular, F27 shows that the walls of the wheelpit were prevented from buckling by wooden beams that were tied into the structure and rested upon a bedrock lip (the wheelpit was cut into bedrock). Furthermore, the historical fills indicate that adequate water drainage was an important concern; they functioned to drain water away from the furnace structure. The information provided by the 24 features was significant to an understanding of the mechanics of the site, especially since such information was not duplicated by historical sources.

Also of particular significance within the furnace area were the samples of iron and slag that were found in situ. These included a part of a cast cauldron, a fragment of architectural pattern, and numerous pieces of iron in various shapes. Together these samples provide a means of investigating technological problems that may have been encountered by the industry since the specimens reveal the metallurgy employed at the site. For instance, a high-sulphur iron would have presented problems in casting hollow ware. Such observations would be pertinent to the question of why the industry did not develop sufficient markets or profit.

The worker housing area was assessed through test pits and surface collecting. The test pits indicated that the present building line along the east side of Main Street is the same as the historical building line. Thus it is clear that Main Street has not been widened on the east side. The samples of materials collected from the backyard gardens included a variety of ceramic wares and the number of surface ceramics was quite high. For instance, 88% (97) of all collected items within the backyard garden (40m²) of No. 18 Main Street were ceramic, of which 10% were mid-19th-century patterns. These materials served to indicate that a substantial amount of refuse has been discarded at the rear of the property over time, and that significant deposits of historical artifacts are likely located within the worker housing area.

DISCUSSION

There are three viewpoints from which the archaeological potential of the Marmora Ironworks can be assessed: technology, lifeways, and social process. From a technological viewpoint, the artifacts of the furnace area are important for they document aspects of metallurgy at the site. Determining to what extent smelting at the site was successful is an important element of this research since the industry failed in various attempts to become successful. This may have been the result of inadequate skills in producing a marketable product. For instance, the treatment of the magnetitic ore may have presented significant problems to casting wares. If the iron had a high sulphur content it would cause the iron not to flow properly and hence ruin the casting. Given that the market for cast hollow ware was important to the industry, such problems would have had a profound affect on the success of the ironworks. The iron artifacts and waste products at the site may be used to address this issue.

In addition, the features of the furnace area are significant from a technological perspective for they reveal the mechanics of the site. Historical information indicates that the technology shifted over time, but particular aspects and details of the mechanics are not known and can only be discovered archaeologically. These include the knowledge of the type and size of machinery, the methods of drawing water power, the design of the blast system, etc. A cylindrical blowing apparatus was used at the site in what was most likely an attempt to increase furnace production. These aspects can only be understood through the archaeological evidence and are important in revealing the technology employed in the several attempts to produce iron more efficiently.

Moreover, the iron remains from the Marmora Ironworks site constitute the only known examples of iron produced in Upper Canada during its early period of settlement.

From a lifeways viewpoint the area of the worker housing is of particular importance. Although little archaeological evidence is available at present, it appears likely that significant deposits of artifacts are located within the backyard areas of the worker houses. These artifacts would be of particular importance in addressing issues of socioeconomic status, subsistence, trade network, etc. Additional historical study would be of benefit to this type of research, particularly it would be valuable to construct an economic profile of the community and attempt to isolate difference that may be pertinent to archaeological research.

It is of particular interest from a social process standpoint that the Marmora Ironworks eventually failed completely, and that the Marmora community shifted to other economic avenues. An historical study of economic and social trends has shown that this had a significant affect on social composition and the structure of the work force. To what extent this can be seen archaeologically is at question, but it is likely that changes in social structure may be seen at a neighborhood level. As the worker housing area shifted to become a residential village center, distinctive changes in social and family composition likely occurred.

Overall the significance of the site can be viewed in terms of Ontario's resources and in terms of themes in current research. The Marmora Ironworks site is unique in Ontario since other similar sites have been severely impacted in the past. Information from this site is not duplicated elsewhere in the province and is a unique resource. It contributes the only known intact archaeological evidence of early ironmaking in Upper Canada.

From the perspective of current research, a number of archaeological and historical studies on ironworks have been undertaken in northeastern North America and the study of the Marmora site contributes to this body of research. The excavations of the Saugus Ironworks in Massachusetts and Les Forges du Saint Maurice in Quebec are well known examples of this type of study. Recent archaeological research includes the examination of iron kiln remains in Vermont by Rolando (1984),the examination of roasting ovens in Connecticut by Raber (1984), the investigation of the Denbrook Forge and Mill Site in NewJersey by D'Angelo (1984),the investigation of the Long Pond Furnace Site in New Jersey by Rutsch (1984), and the investigation of Les Forges L'Ilet in Quebec by a group from the Universite de Quebec a Trois Rivieres. In addition, recent historical and economic research has been undertaken on ironworks and ironmaking communities. Examples of this type of research in Canada include the historical study of the St. Francis Ironworks in Quebec by McDougall (1984), and the economic study of the Canadian charcoal-iron industry of the late nineteenth-century and early twentieth-century by Inwood (1983). Also, a modest body of comparable literature is available on studies undertaken in the United States. This work shows the degree of interest that has developed in the study of nineteenth-century ironworks, of which the excavations at Marmora are a part. The research in Quebec is of particular importance in this regard for comparisons between the industries of Lower and Upper Canada may lead to significant insights into iron manufacture and ironmaking settlement from a regional perspective.

ACKNOWLEDGEMENTS

Archaeological investigation of the Marmora Ironworks site was made possible by a grant from the Ontario Heritage Foundation. Thanks are extended to Gregoire M. Crevier for undertaking the archival research for the archaeological project, and to Richard Gerrard for drafting the figures for this article.

REFERENCES CITED

- Boyce, Gerald E. 1967 Historic Hastings.Ontario Intelligencer Limited, Belleville, Ontario.

- CR 1861 Census Returns (CR), on file at the Ontario Public Archives, Toronto, Ontario.

- Craig, Gerald 1963 UpperCanada:The FormativeYears,1784-1841.McClelland and Stewart. Toronto, Ontario.

- Crevier, Gregoire M. 1985 Background Research: History of the Marmora Ironworks. In Excavations at the Marmora Ironworks: Results of the 1984 Field Season (G. Graffam, editor). Report on file at the Ontario Ministry of Citizenship and Culture, Toronto

- CVCA 1974 History of the Crowe Watershed. Report on file at the Crowe Valley Conservation Authority (CVCA), Marmora, Ontario.

- D'Angelo, James 1984 Denbrook Forge and Mill Sites: Archaeological Investigations, Morris County, N.J. Paper presented at the Historic Iron Studies Workshop, Society for Industrial Archaeology, Greenwood Lake, New York.

- Graffam, Gray 1985 Excavations at the Marmora Ironworks: Results of the 1984 Field Season. Report on file at the Ontario Ministry of Citizenship and Culture, Toronto.

- Hayes, Charles 1828 Memorial of Charles Hayes to Sir George Murray. On file at the British Public Archives, London, England.

- HCRO Deeds 1002, E-1668, F-2297,F-2483.Hastings County Registry Office (HCRO),Belleville, Ontario.

- Hetherington, Thomas 1830 Marmora Iron Works. The Kingston Chronicle (newspaper) December 25, 1830, Kingston, Ontario.

- Inwood, Kris 1983 The Decline and Rise of the Canadian Charcoal Iron Industry, 1867-1913. Paper presented at the Economic History Workshop, St. Mary's University, Halifax, Nova Scotia.

- McDougall, David J. 1984 The St. Francis Iron Works, Quebec, Canada. Paper presented at the Historic Iron Studies Workshop, Society for Industrial Archaeology, Greenwood Lake, New York.

- Manahan, A., and Ridley, G.A. 1839 Report of the Removal of the Penitentiary from Kingston to Marmora. Report on file at the Public Archives of Canada, Ottawa, Ontario.

- Michael, Rita 1983 Ironworking in Upper Canada: Charles Hayes and the Marmora Works. Canadian Institute of Mining and Metallurgy Bulletin 76 (849):132-134.

- Palmer, Bryan D. 1983 Working Class Experience: The Rise and Reconstruction of Canadian Labour, 1800- 1980. Butterworth. Toronto, Ontario.

- Pentland, H. Clare 1981 Labor and Capital in Canada, 1650-1860. James Lorimer. Toronto, Ontario.

- Raber, Michael 1984 Partial Recording of the Ore Roasting Ovens at the Mine Hill Iron and Steel Making Complex, Roxbury, Connecticut. Paper presented at the Historic Iron Studies Workshop, Society for Industrial Archaeology, Greenwood Lake, New York.

- Rolando, Vic 1984 Vermont's Charcoal Iron Industry: The Industrial Archaeology of Kiln Remains. Paper presented at the Historic Iron Studies Workshop, Society for Industrial Archaeology, Greenwood Lake, New York.

- Royal Commission 1890 Report of the Royal Commission on the Mineral Resources of Ontario and Measures for Their Development. Printed by order of the Legislative Assembly. Warwick and Sons. Toronto, Ontario.

- Rutsch, Edward S. 1984 Iron-Making at the Long Pond Furnace Site. Paper presented at the Historic Iron Studies Workshop, Society for Industrial Archaeology, Greenwood Lake, New York.

- SUC 1857 Statutes of Upper Canada (SUC), 3rd Session, 5th Parliament, Chapter CLXXIX. 1865 Statutes of Upper Canada (SUC), 4th Session, 8th Parliament, Chapter CLXIX.

Department of Anthropology Trent University Peterborough, Ontario.