The Founding of Deloro, a mining town

Further information on the History of Deloro can be found at the Archives of Trent University. This collection was in the custody of Professor Roy Bowles and Professor Morgan Tamplin before it was donated to Trent University Archives in 1998. http://www2.trentu.ca/library/archives/98-018.htm

Gatling Gold Mine 1872, water colour, pen & ink by C. Walker, now in the R.O.M.

Isabella and George Davidson were residents of William's Mine (Lot 7 Conc. 9, Marmora Twp) arriving by wagon from Belleville c.1870. Also living at Williams Mines (also known as Lower Deloro) were Mr. & Mrs. Edward Archer and son, William Archer, born 1874.

Canadian GoldFields secured the property in 1896 and erected a large mill at Marmora station. The ore was treated using the bromo-cyanide process (Sulman-Teed process) for nearly a year when the mill and plant was destroyed by fire. At that time the management of the plant was put in the hands of Mr. P. Kirkeqaard. A new stamp mill was erected at the mine site and a double process (amalgamation followed by the bromo-cyanide treatment) was begun which proved to be a great success. (Click here for details)

After the discovery of gold at Eldorado in 1866, a great amount of activity was shown in the Deloro area with at least 25 shafts being sunk on the site. The Severn mine (Pearce Mine) which is located on the east side of the Moira river was supposedly opened in 1868.

The present site had a number of owners and/or companies involved. The Hawkeye Property, the W. J. Gatling (Brother of the inventor of the Gatling gun), the Gatling Company, the Tuttle property, the Severn property and quite possibly the Cook property. The Deloro Mine which included the Gatling and Tuttle shafts was first opened by the Gatling Gold and Silver Mining company in 1873. This company spent several thousands of dollars developing the property which sold out to Canada Consolidated Gold Mining Company.

For more technical details, maps and photos, see the Golder Associates Apr. 2012 report : Click on Part 1, and Part 2 and Part 3

Canada Consolidated obtained the property in 1880 and imported from Pennsylvania, a French mining engineer, Rene Claude Earnest Gaujot (1840-1909) to act as superintendent, The company spent extravagant sums of money in buildings and plants but made a complete failure in treating the refractory mispickel ores (arsenopyrite) by their chlorination process. In 1883 expenditures reached 200,000 dollars, work was suspended and the personal property of the company was sold under execution. Work continued two years longer under lease and then given up as a complete failure. Arsenic production is reported as 440 tons in 1885, 120 tons in 1886 and 30 tons in 1887 etc. There is no mention of gold having been recovered.

c.1898

1896 Labratory and Dry Crushing Mill, 3rd mill to be built in Deloro

In 1901 the number 3 level was 426 feet 3 inches long and the number 4 level was 393 feet 6 inches long. There was extensive cross cuts as well as working in the Tuttle and Red Shafts. The ore was worked exclusively for the gold and the arsenic was purely a by-product. It should be noted that the tailings from the previous operations was successfulIy reworked using the new process.

The"Report of the Ontario Bureau of Mines-1901 ", page 115-116 states"At the presenttime the arsenic plant is undergoing complete reconstruction for the purpose of securing a large yield at reduced cost per ton. The difficuIties formerly experienced at Deloro from the loss of arsenic andthe consequent imperiling of livestock in the vicinity, have been entirely overcome by modifications etc. No cases of arsenic poisoning have occurred, great care being observed to precludeaccidents of this sort".

In 1901, this was the only arsenic producing plant on the American Continent manufacturing arsenic (99.4-100% pure AS2 03) on a commercial scale. Production was 50-60 tons per month and 700 tons (valued at $42,000) was sold in 1901for use in pesticides, fertilizer and even cosmetics.

Disastrous Fire May 12, 1898

On Sunday morning about 4 o'clock fire broke out in the big mill belonging to the Canadian Gold Fields Co. at Deloro. The fire originated from the drying machines, where the men left fire at 12 o'clock, midnight, and went home. There was a big wind blowing, and one of men was awakened near by and went in to try and save some precious belongings, and he states the whole inner partitions were all ablaze when he got there. It is said that the mill was insured for $41,000. The company was just erecting a new crusher in the same building, and in- tended to operate the machine this week. It is said that there was a quantity of gold under treatment in the laboratory, about $8000. worth. The laboratory was a complete wreck, not 'one thing being saved. A pair of scales was burned valued at $250. About 30 men were thrown out of employment. Loss estimated at $75,000. The insurance was with Norwich Union.

North Hastings Review

Also, it is reported that for the first time in the world the Harris Air Lift was used for dewatering mines at Deloro.

In 1902 the mine was flooded and eventually pumped out because the company needed all the arsenical ore from the area to make a profitable recovery. Canadian Goldfields continued until 1903 and had recovered over $300,000 worth of gold and arsenic.

From 1899 to 1904, the Atlas Gold and Arsenic Mining Co. (Gatling 5 Acres Shaft) also took out substantial quantities of these materials.

In the fall of 1903, silver deposits were discovered at Cobalt, Ontario, and by 1904 efforts had been made to resume production at Deloro using the Cobalt area ores. By 1905 the 0'Brien Mine (owned by M. J . 0'Brien) was in production and by 1906 severaI mines were producing with 5,335 tons of ore being shipped. The ore contained 160 tons of nickel, 321 tons of cobalt, 1440 tons arsenic and over 5 miilion ounces of silver. The mine owners received no payment for the cobalt, nickel or arsenic.

Deloro Mining and Reduction Company (1907-1916)

Report by Golder Associates, April 2012

The Deloro Mining and Reduction Company was incorporated in 1907; the same year in which Canadian Goldfields Limited was dissolved. Just as the Canadian Goldfields mining operation was facing ruin because of its flooded mine, a complex ore of silver, cobalt, nickel and arsenic was discovered in the fall of 1903 at Cobalt in Northern Ontario. Mining began in 1904. Rail connections between Cobalt and the southern Ontario network were completed in 1905. This ore, like that at Deloro was an arsenopyrite. The silver was by far the most valuable component of the ore but arsenic was the largest constituent by tonnage. As mined in 1904, the ore, by weight, consisted of six percent silver, 13 percent nickel, 15 percent cobalt and 66 percent arsenic.

gRACE WARREN ON THE WOLFE STATION PLATFORM AWAITING HER TRAIN, ALONG WITH $260,000.00 IN SILVER BUILLION FROM dELORO

THE MARMORA HERALD REPORTS:

Aug. 29 1907 A new 150 h.p. gas engine weighing 9 tons is being installed in the new Cobalt Plant at Deloro. Gas will be manufactured direct from coal on thespot and also the coke used in refining arsenic.

Feb. 18, 1909 Because he travelled around Toronto selling ounce igots of silver worth 50 cents to jewellers and second-hand dealers for 35cents, William Kevz, a Finlander lately in the employ of Deloro Refining Co. was arrested in that city. The police suspected he stole the silsver in Deloro and shipped it to Toronto,

FEB. 10, 1910 It is alleged that Deloro Works have been systematically robbed for some time. Three arrests have already been made and a considerable quantity of refined silver and silver ore have been found. The Crown is taking active measures to protect the property of the Company.

February 10, 1910

SEPT. 19, 1910 On Wednesday of last week The Deloro Mining & Reduction Co. expressed $44,000.00 silver in 70 lb bars on Central Ontario Railways. This is just an average weekly shipment. The arsenic by-product is also very favorable.

Michael J. O'Brien.

After gold mining shutdown at Deloro, the General Manager (Peter Kirkegaard) had kept the mill open doing custom work for other area mines. At the same time Dr. S.F. Kirkpatrick, head of the Mining School at Queen’s University and a metallurgical consultant for Canadian Goldfields, continued his research in refining arsenical ores. The two men believed they had both the technical expertise and the physical plant to refine the Cobalt ores. They contacted Michael John O'Brien, a very successful colourful Renfrew businessman with a passion for money and hockey, later railway contractor and mine speculator who had acquired some of the most valuable Cobalt mining areas. O’Brien was convinced to invest $75,000.00 in a small plant at Deloro that was completed in 1906. The refinery began operating in 1907 and the Deloro Mining and Reduction Company was incorporated to operate the property.

Click here to read more on O'Brien

In 1910 when cobalt began to show possibilities in the world market, O’Brien expanded the plant to produce both cobalt and nickel oxides. Kirkpatrick convinced the Ontario government that they should fund his research on cobalt at his lab at Queen’s.

The new cobalt plant required additional electrical power. The original, steam-driven generator, installed by Canadian Goldfields in 1900 was shut down in 1909. Electricity was instead purchased from the Seymour Light and Power Company’s hydroelectric plant located 35 km away at Campbellford. The Bishop Construction Company of Toronto, was awarded the contract for the erection of a substation in Deloro. It is assumed that the concrete transformer building that still stands in 2011 was built in 1909 when this change-over occurred.

Marmora Herald - May 1907

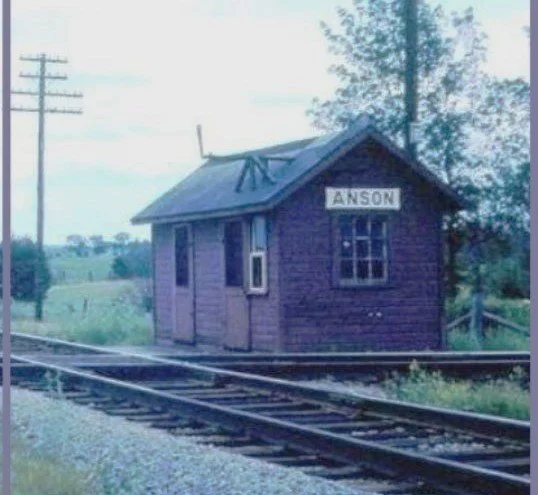

"A spur line is being surveyed from Marmora Station on C.O. Railway to Deloro. A road will be built on which to ship ore and coal."

Inexplicably, the Deloro smelter did not receive a rail connection until 1913. All ore was brought by rail from Cobalt to Marmora Station and trans-shipped into wagons for the two kilometre trip to Deloro. Possibly, the quantity of ore received was initially not sufficient to justify the cost of the spur line. Possibly, O’Brien was being cautious and not investing more than absolutely necessary until both the metallurgical process and markets for cobalt were well established.

Cobalt prices were quite volatile in this period. Prior to the Canadian refining of cobalt ores, cobalt oxide wasselling at $2.50 per pound. Production from the Cobalt district soon glutted the market and by 1912 the retail price quoted in New York was about 90¢ per pound and in England about 68¢.

Peter Kirkegaard has resigned his position as Managing Director of the Deloro Mining and Reduction Co., with a view to taking up private practice of his profession. Marmora Herald Feb. 16, 1911

(In April of 1911, Peter Kirkgaard and Reginald Burton of London, England, bought the Donahue Mining Claim in Tisdale Township, Porcupine. Mr. Kirkgaard was also an owner of the Cordova Mine)

the deloro dinky

The Deloro Dinky

Annmarie Willman-Spry wrote: Bunny Gifford was an engineer on that train. James Dalton added: George O'Neil was the driver when we were kids

The Coniagas Reduction Company and the Canadian Copper Company were the two main competitors for Deloro. The Coniagas Company, wholly owned by the Coniagas Mines Limited of Cobalt, Ontario, opened a smelter at Thorold, Ontario, in 1908. The company operated successfully for a number of years. Conversely, the Canadian Copper Company closed its cobalt plant in 1912 as a result of the collapse in cobalt prices.

Deloro had one advantage over its competitors in that it also sold a cobalt product called Stellite, as well as cobalt oxide. In the early 20th century, an entrepreneur in Kokomo, Indiana, Elwood Haynes, began experiments to develop a stainless metal. In 1907 he patented an alloy of cobalt, tungsten and chromium that he called Stellite. Since Haynes required cobalt, the only place he could get it in large quantity was from Deloro. Thus in 1912, as the price of cobalt oxide deteriorated, Deloro Mining and Reduction began producing high-value Stellite under contract to Haynes.

The demand for Stellite varied considerably in the early years. During the First World War it was in high demand for military uses but after the war the demand shrank considerably. In 1919 the son of M.J. O’Brien, Ambrose, went to England to explore markets for cobalt and Stellite. One result of his visit was the opening of a Stellite plant in Birmingham. Deloro became the world’s leading cobalt producer in 1924. Stellite is still manufactured today by Deloro Stellite, a multinational company that had its origins with the Deloro Mining and Reduction Company. In 1909 Hydro electric power lines were installed from the Trent River and a railway spur line connected Deloro to the Central Ontario Railroad in 1913.

May 22, 1952

The results of experimentation by M.E. Haynes and Prof. H. T. Kalmus of Queens University was applied in production and in 1914 Deloro manufactured the first cobalt metal (226,079 Ibs.) to be produced commercially in the world. This led to the production of stellite a much sought after war material.

Mr. Haynes gave his discovery the name Stellite, which is derived from the word Stella, the latin word for star.

Dec 16, 1909

The fatal accident of Kust Bikki

Deloro accident - A.H. Thornton Marmora Herald Feb. 28, 1918

1916 Deloro Mine Site from the east bank of river. Note 1882 arsenic works centre still in use. Arsenic bag house on right; Cobalt oxides plant on left

FOREIGNER ARRESTED

A foreigner, who went by the names of Hill and also Lappe, came up before Judge Deroche on Wednesday of last week for stealing a quantity of silver from Deloro Mining & Reduction Company. He was sentenced to the Provincial Reformatory for two years less a day.

February 3, 1916

INCORPORATION OF THE VILLAGE OF DELORO Jan 1, 1919

On Feb. 15, 1918, The Deloro Smelting and Refining Co. took the formal step of making application to the Legislative Assembly to incorporate their lands into a formal Municipality. It was not without the objection of the Municipallity of Marmora and Lake in whose juristiction the property was situate. However, the company received permission and on January 1, 1919 the Village of Deloro was Incorporated. On Jan. 9, the Herald reported the results of the first election: Reeve - S.B. Wright, Councillors - R.A. Elliott, F.A. Bapty, J. Judge and S.Simmons

May 25, 1916

Sept 4, 1919

1917

May 19, 1921

ONTARIO REPORT on the Mining Accidents in Ontario in 1927

Deloro Smelting and Refining Company

The Safety First Committee of the Deloro Smelting and Refining Company, with R. A. Elliott as chairman, continued a very active campaign against accidents during 1927. They were successful in reducing the number of compen- sated accidents for the year to five. There are approximately 362 employees.

The decline in accidents each year is shown by the following figures taken from the chairman's annual report for 1927. Figured on a per centage basis the lost time was:

1923 0.635% of the total time. 1924 .509 1925 .233 1926 .160 1927 .071

This reduction in the number of accidents and lost time was due to co-operation of the management and employees with the safety committee. Each accident was carefully investigated and classi- fied under one of the following causes : faulty equipment, wrong method of work, carelessness, doubtful or accidental. Cash prizes were awarded to 33 employees for worthy suggestions. Three foremen for departments received rewards for the best no-accident record of the year.

In 1916 the company' s name was changed to the Deloro Smelting and Refining Co. By 1917 the company employed 400 men in a series of plants destined to irretrievably pollute the stretch of the Moira River they sat along while manufacturing refined silver, refined arsenic, Cobalt oxide, metallic cobalt, nickel oxide and stellite.

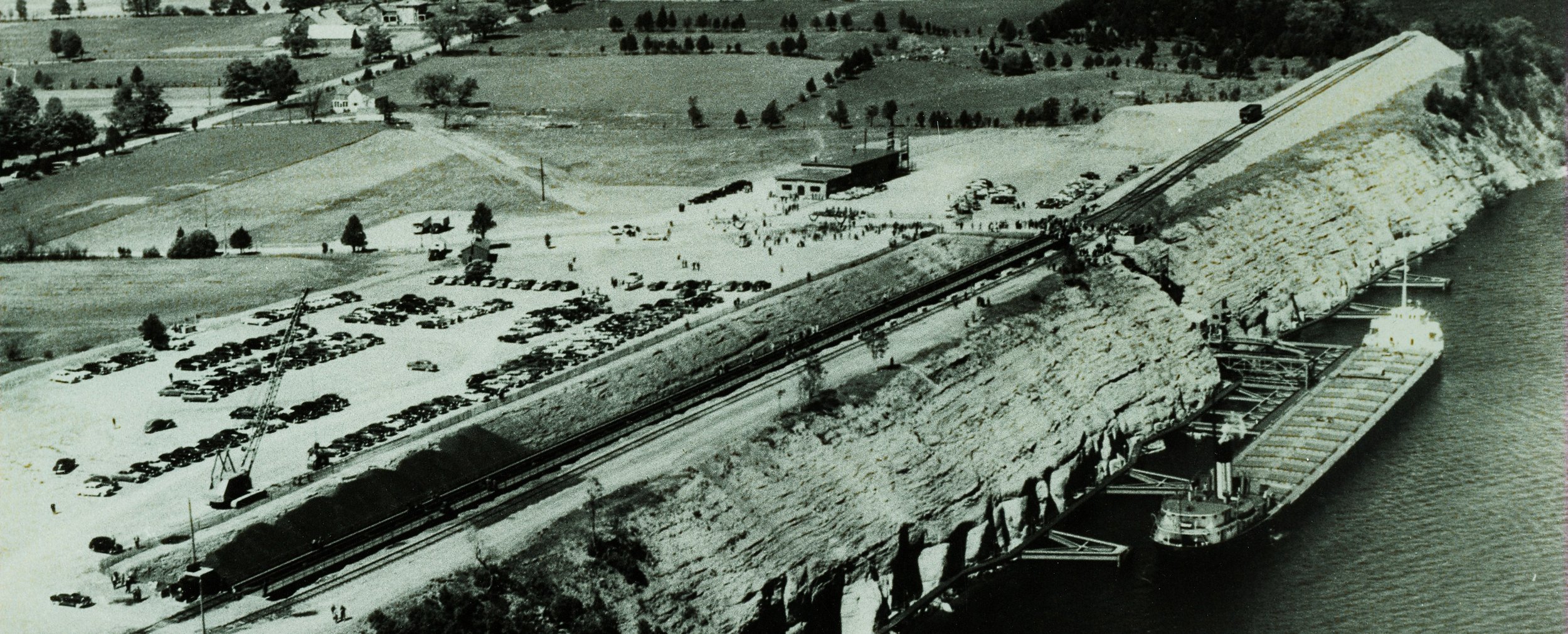

On 25 March, 1920, 96 railroad cars of silver weighing over 8,500 pounds left Marmora Station heading for China.

Dwindling world markets for cobalt in the 1920's lead to large scale layoff, however when several silver mines closed in Cobalt, Ontario, after 1929, the silver cobalt ore was shipped to Deloro and stockpiled. This kept the company operating until World War II when the demand for cobalt boomed.

Also from 1932 to 1937 the hand cobbed ore shipped by the Eldorado Mine at Great Bear Lake, North West Territories to its Port Hope refinery, along with the residue from the refinery, was sent to the Deloro Smelter for re-processing.

Deloro Smelting and Refining Co 1936.png

This packing crate was owned by John (Jack) and Olive Vincent from Beaver Creek. It's now owned by their Great Granddaughter, Lorilei Wells Mayhew, who submitted the photo.

By 1940 wartime events were secretly brewing which made it inevitable that Canada's help would be sought as a supplier of materials essential in the making of an atomic bomb. The Eldorado Mine uranium deposits at Great Bear Lake were among the richest in the world and their facility at Port Hope, Ontario, was the only uranium refinery in operation in North America. And as it happened, Port hope also had a substantial stockpile of uranium oxide, a fortuitous by-product of radium refinery, later used by the US military in the production of the atomic bomb. Deloro once again was a facility for re-processing, this time, uranium ores. Interestingly, a Deloro employee, Harry Simpkinson, moved out to Trail B.C., where "heavy water" was being produced for the US military.

Councillor Linda Bracken presented Hawthorne with a framed certificate of appreciation from the municipality, recognizing her achievement and thanking her for her "determination, compassion and enthusiasm to make sure the history of the Deloro Mine Site is preserved.

The poignant and powerful documentary, produced by Heather Hawthorne, which is available at area libraries and at Trent University, was completed in 2012, was first screened at a public information session in Deloro.

During World War II Deloro was also the only cobalt plant in North America and operated mainly on cobalt-copper-iron alloy residues from Northern Rhodesia plus a supplementary supply from the Belgium Congo. No Canadian concentrates were treated as the imported ores were more highly concentrated.

Following World War II the Deloro Smelter went back to treated ores and concentrates from Cobalt, Ontario but at a reduced rate. From 1944 to 1952 the Deloro Smelter treated the 19.7% speiss residue from the Port Hope refinery and a smaller quantity of hand cobbed cobalt from the Eldorado Mine.

Eight lean years followed. The Korean War and United States Gov't contracts for the treatment of Moroccan ore kept the plant operating full strength untiI 1958. The company employed as many as 500 workers. Belgium competition, falling world prices and the decline of silver mining in the Cobalt area dealt the company a crushing blow. There were no substantial customers to use the company's smelting and refining facilities. So in March 1961 the plant closed down and the chemical and research laboratory was moved to the Belleville plant of Deloro Stellite, a subsiduary of Deloro Refining & Smelting Cos.

Deloro Smelting and Refining Company Limited, 1917-1961

This is a reverse image of the Marmora Herald Newspaper stamp, used for letterhead printing

Click here to read David Caldow's 1927 description of life as a Deloro worker

Fire at Deloro1928

On Sunday evening, June 20th,a fire occurred in the Oxide Plant at Deloro which resulted in quite a heavy loss and might have had very serious results. The fire is reported to have been caused by a break in one of the oil pipes. The oil became ignited and caused a spectacular blaze. The roof of the Oxide building was quicklydestroyed and about everything that would burn in the building. The railroad locomotive, which was on the track beside the building was also destroyed. Fortunately no loss of life resulted and while the loss is heavy it will be covered by insurance. As a result of the fire part of the operations at the plant will be interfered with for a time, but the building and plant will be replaced or repaired as soon as possible.

Marmora HeraldJune 21, 1928

Report by Golder Associates, April 2012, continued

In 1917 the Deloro Mining and Reduction Company was reorganized as the Deloro Smelting and Refining Company Limited. This event marked a large capital expansion in the operation. A “metals building” for Stellite production, a new office, and a warehouse and bag house for arsenic production were completed in that year. The previous year a plant to manufacture aluminum dust, used in refining silver, was completed

Deloro Chemical Co. Arsenic Advertising

A water sprinkler system was also installed in 1917. The tall water tower became a prominent landmark. However, the system did not stop a fire in the spring of 1919 when the engineer’s office, carpenter shop, and weigh scales were destroyed. Presumably these buildings were not provided with a sprinkler system. In the fall of the year, the Twenty-Stamp Mill, powerhouse, and concentrator – which were being used as storage, also burned. Only the laboratory building survived. This group of buildings were far removed from the main mill.

At about 1918, O’Brien acquired a cobalt refinery at Fredericktown Missouri; the only cobalt refinery in the United States at the end of the First World War. The company was bought on the recommendation of S.F. Kirkpatrick, the Managing Director of Deloro Smelting and the metallurgist who had perfected the refining of arsenical gold ores for Canada Goldfields. Unlike the Cobalt, Ontario, ores, those from Missouri were sulphide and required a different smelting process.

During the early 1920s, the silver and arsenic departments worked continuously. The cobalt and nickel plants were more variable. In 1921 the oxide plant was closed and the following year operated for only six months. The Fredericktown’s plant was also unsuccessful and closed in 1925, probably due to a slump in the cobalt market and possibly because of refining problems

The success of arsenic production at Deloro into the 1920s was driven by the demand for insecticides; particularly to control the boll weevil crisis. By 1922, 87 percent of the cotton producing areas of the United States had been affected by the weevil. Calcium arsenate was determined to be the cheapest and most effective method for controlling the insect. Deloro began producing lead and calcium arsenate. By 1919 the demand was such that the company constructed a separate insecticide plant and the following year the Deloro Chemical Company was incorporated. The company also produced various cobalt compounds including cobalt sulphate, acetate, nitrate, chloride, hydrate, and carbonates.

The global price of cobalt metal fell dramatically with the opening in 1925 of large copper-cobalt deposits in the southern province of Katanga, in the Belgium Congo (today the Democratic Republic of the Congo). Katanga cobalt could be produced cheaply since it was a by-product of copper refining. Deloro Smelting was selling cobalt metal at $2.35 per pound; the Belgian company in Katanga charged $1.25 per pound. Fortunately (for Deloro) before competition became ruinous, the Belgian company experienced refining problems. Kirkpatrick was able to negotiate an agreement by which Deloro Smelting would provide technical assistance and the Belgian company agreed to split up the world market; in other words form a cobalt cartel.

During the late 1920s, the supply of silver-cobalt ore from Cobalt began to diminish. By 1929 Deloro’s smelting operation was curtailed by the lack of ore supplies. Depressed markets caused by the onset of the Depression minimized the effects of the dwindling ore supply. In fact, in 1930 Deloro Smelting started to stockpile cobalt for future use. Stellite production provided a partial cushion for the lack of markets for cobalt metal in general.

1939 Deloro Smelting & Refining Co display, Joseph Hulsman Sr.

Interview with former employee, Ted Bedore, in 4 parts

Part 1 - Deloro Smelter and Refinery: Cobalt and silver

Part 2 - Deloro Smelter and Refinery: Arsenic Bag House

Part 3 - Allergy to Arsenic

Part 4 - Hard working conditions

With the decline of production from Cobalt, Ontario, Deloro Smelting began to import cobalt ores. The cartel that began with the Belgian company in Katanga was expanded in 1932 to include a Northern Rhodesian (today Zambia) company, known as the Rhokana Corporation, and later a company working in Morocco. In 1935 an association of German cobalt producers joined the “trade pact” and a Finnish company followed the next year.

The Chemical Laboratory in the '40s

A new domestic source of cobalt became available at Deloro when, in 1933, Eldorado Gold Mines Limited(despite its name) completed a refinery to extract radium at Port Hope, Ontario.The process produced a radioactive waste that contained 3.5 percent cobalt. The Port Hope refinery concentrated this waste into a speiss with 12.75 percent cobalt that was then shipped to Deloro for further refining. This source of cobalt speiss apparently produced the radioactive slag found on the Deloro Mine Site today.

With the onset of war, in October 1939 the Belgian company and Rhokana Corporation asked Deloro Smelting to take up their refining obligations. Ore from both companies was processed in Belgium. When the country was invaded by Germany in May 1940, Deloro Smelting had to modify its refining process as the Rhokana ores were 40-44 percent cobalt compared to the ten percent ore from Cobalt, Ontario. The new ores also did not contain arsenic which seems to have accounted for the reduction in arsenic production during the 1940s.

Deloro 1946 On the right, the labs 1946 donated by Robin Riddihough

New Lab, Deloro Mine, built by Sullivan Gang,

Cobalt became a strategic metal during the Second World War. As an indication of its importance, Deloro Smelting completed a new research laboratory in 1940. A new chemical laboratory and sample room were constructed one or two years later. In 2011 the research laboratory still stands and is used as the arsenic treatment facility; the chemical laboratory has been demolished.

In 1942 a United States Government agency, Metal Reserve Company, contracted with Deloro Smelting to supply 7,000 tons of cobalt concentrate. When the contract expired in 1944 the government changed its policy and stockpiled the concentrate at the Deloro smelter property. The stockpile was moved to New Jersey between 1947 and 1948. The following year the United States government decided to add to their stockpile by purchasing 60 tons of cobalt a month from Deloro Smelting. The contract lasted until 1958. By 1959, the Deloro plant had a capacity of only 35 tons per month. Thus the existing facilities had to be rebuilt and expanded. In 1958 the Canadian government also decided to purchase cobalt and stockpile it at Deloro.

Click here to read R.G. Walsh's 1953 Chamber of Commerce Speech on "Cobalt"

During the era of Deloro Mining and Smelting, the former mining area north of the industrial plant was used for a variety of industrial activities and for workers housing. The laboratory that had been associated with the Canadian Goldfields continued to operate for some years. An insecticide building was completed. The area also contained two bunkhouses, a kitchen and dining room.

Pat McCrodanwrote: In 1956 when I worked in the primary treatment Office, Lavender trucks used to back up the trestle and dump lime from Beachville

Plant Closure

Although the Deloro Smelting and Refining Company plant had been rebuilt in the early 1950s and the company continued to flourish, the rural, isolated location of the industry became a growing liability. Fewer people were willing to work within the company town environment of Deloro. As well, the company itself had become part of a larger international operation.

In 1956 some of the operations were moved to a new facility in Belleville in order to be closer to schools, transportation, and an urban environment that would attract skilled employees.

In 1961 the Deloro Mining and Smelting Company completely shut down its Deloro plant.

Fifty years of refining and smelting arsenical ores at Deloro had contaminated the land. However, a broad public awareness of environmental issues was still in its infancy in the 1950s. At that time the Deloro plant was still an economic boon to the region. Only during the 1960s did the environmental concerns begin to become evident.

WAS THE HERALD UNION BUSTING?

THE HERALD 1952

Member of Canadian Weekly Newspapers Association Authorized as Second Class Mail Post Office Department Ottawa

Deloro Strike Ended

Basis of Agreement Reached at Meetings in Office of Minister of Labour

The strike of employees at DeIoro Smelting &. Refining Company Limited ended the latter part of last week, but the effects are liable to last for a considerable time. It may be easy to close down a plant like Deloro in a few days, but getting it ready for production again and resuming business operations is a very different matter.

A copy of the basis of agreement between Deloro Smelting & Refining Co. Limited and the Mine, Mill and Smelter Workers Union appears in another page and the more employees study it, the more they will realize they were taken for an expensive ride by the Union, with neither pleasure or profit at the end of it.

The agreement shows that all the employees receive for the next year, over and above what was offered before the strike began, is one extra holiday, while the company pays the difference between the former insurance premiums, and the new one. Had the Union approached the Company in a conciliatory manner before the former contract expired, instead of demanding a 40 hour week and 40 cts. an hour increase in wages before they would consent to negotiate, they could have got the 10 cent increase offered before the strike began. The 10 cents an hour would have meant about $100.00 extra since June 1st , and the saving of around $200.00 they lost by the strike. In fact, before operations can be resumed on a full scale, some of the men may lose a good deal more in wages.

After a year employees are to receive an extra 5 cents an hour and a 42 hour week, but to the majority the extra time will be of no value. The contract runs until June 1st, 1954, which, means there will be no opportunity for further negotiations before that time. Judging by the time wasted throughout the plant in recent months, in talk and arguments about Union affairs, the Company will save a lot more than the 5 cents an hour in having the agreement run to June 1st, 1954.

Most of the employees realize now how badly they were mislead by the Union, both in promises of strike pay and benefits while a strike was in operation, and also in claims of what could be accomplished by a strike. It will take years to make up what they have lost as a result of the strike. Employees who are dissatisfied with the conduct and results of the strike have the privilege of notifying the company, within seven days of the Signing of the agreement, that they wish to have deductions from their pay cheque for union dues discontinued. That would be one way of making a small saving each month and help get rid of Mine, Mill and Smelter Workers Union. Another thing that is making Union members angry is the discovery of the amount of the Local 889 funds that have been used for the benefit of some of the local executive before and during the strike.

Deloro Site maps

1880

1929

1939

1961

1987

The corporate lineage of the Deloro Smelting and Refining Company Limited continues to the present. In 1970 the company was purchased byBritish Oxygen and its name changed to Deloro Stellite Limited (later Inc.). Deloro Stellite Inc. in Belleville was part of a multinational firm known as the Deloro Stellite Group Limited which produced specialty steel alloys using cobalt. Today, the company is known as Kennametal Stelite Inc., having been purchased by an American firm.

In 1970, when British Oxygen purchased the holdings of Deloro Stellite, the Deloro property was not included. Instead the property at Deloro went to new owners Erickson Construction Company Limited also in 1970. (MHF Note: It is believed this corporation was a skeleton company with no assets, simply set up to hold the very polluted Deloro site separate from Deloro Stellite, which may otherwise have been subject to lawsuits.)

The Deloro Dinky